-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

PVC Conduits & Fittings

Features

- Firm core structure ( Double Wall ) gives added die electric properties

- Self extinguishing PVC

- Standard Electrical Black

- Impact Resistant PVC

- Non Corroding

- Non Combustible 2 Hours

- Fire Resistant

- Flexible enough to be bend by hand, yet tough enough to withstand crushing and breaking

- Interior surface significantly reduces the amount of friction when pulling cables through long runs, even in runs with 90° bends.

Strength

Kalister PVC Fittings offer both high impact and high tensile strength.

Non Conductive

PVC eliminates the most dangerous second point to contact in phase to ground faults. The use of separate ground conductor gives a complete and positive ground for the entire system.

Corrosion Resistant

PVC is resistant to external corrosion and pitting and will not rust. This ensures a lower maintenance cost and longer performance life.

Fire Resistance

As a building material PVC offers outstanding performance characteristics. PVC will not burn unless an external flame source is applied, and will not sustain ignition once the flame source is removed. Kalister PVC Conduits and fittings has a flash ignition temperature of 850° F.

Corrosion Resistant

Kalister conduit and fittings are resistant to a wide range of chemicals such as acids, alkalies, or salt solutions.

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

UPVC Cable Ducts & Fittings

KALISTER Cable Duct is designed for concrete encased and direct burial applications of power utility primaries, secondary's, street lighting, and distribution systems. KALISTER Cable Duct complies with NEMA TC-6 & 8, and ASTM F-512 for utility duct and are rated for use with 90° C conductors.

We manufacture Cable duct in conformity with various Middle East standard and vendor specifications.

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

PE CABLE DUCTS AND INNER DUCTS

KALISTER Innerduct is a flexible raceway manufactured from High Density Polyethylene (HDPE) for use in underground and innerduct applications. Smooth wall offers superior protection, increases pathways of existing duct systems, allows extra channels for future cabling needs, and is ideal for jetting cable. Available in a wide range of sizes, colors, and options

Applications: Underground (direct bury), or placed inside existing duct (innerduct)

Installation methods: Plowing, open/continuous trench, directional boring or pulled through existing conduits.

- Sizes 1/2" - 4"

- Multiple colors and stripes

- Primarily manufacture in wall thicknesses SDR 13.5 and SDR 11

- Also available in wall thicknesses of SCH 40, SCH 80 and SDR 13.5 on special orders

- PE Sub ducts are manufactured and tested for quality as per DIN 8074,

- 8075 and special requirements of various authorities.

- Complies to MOC , Kuwait requirements

Optical Fibre telephone cablesystem

HDPE Single Subducts

Polyethylene single subducts aremanufactured and tested for quality as per DIN 8074, 8075 and special requirmentsof Ministry of Communications, Kuwait. HDPE single Subducts are supplied in coils with lenghts up to the requiments of M.O.C. contractors.

Dimensions

Outside diameter mm Wall thickness mm Inside diameter mm 25 2.0 21 32 2.0 28 40 2.0 36 50 2.0 46 Technical specifications of HDPE Subduct

Density : 0.94 g/cm3 Melt index : 0.4 - 0.7 g/10min. Conefficient of linear expansion : 1.5 x 10 -4 K -1 HDPE Single Subducts Accessories

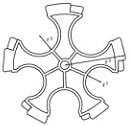

1. Sub-duct holder

It plugs the U-PVC Telephone cable duct allowing passage of HDPE Single Subducts. The Sub-duct holder is made of Polypropylene resistant to acids andalkalies heat and humidity

r1 r2 r3 r4 12.5 16 49 21

2. HDPE subduct Plug

-a- for empty subducts. (blind)

-b- for subducts with cable (with hole)*

d1 d2 h1 h2 21 13.5 35 35 28 15 35.5 4.5

* Sizes of other holes will be available upon request

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

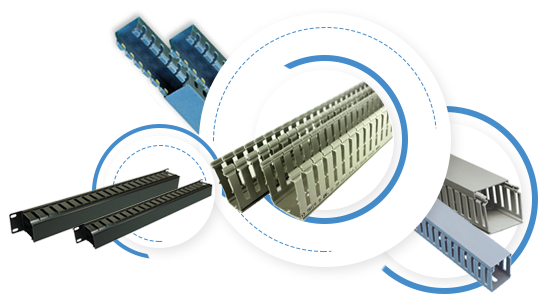

PVC Trunking System

The PVC Panel Trunking are manufactured from thermoplastic resin that can be used in temperatures up to 85°C. Available in GREY and WHITE colours. More slots and smaller gaps in between gives wire tracing and troubleshooting easy for technicians. Rugged Construction and added Mounting slots are available. The PVC Panel Trunking and manufactured from thermoplastic resin that can withstand temperature up to 85° cent.

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

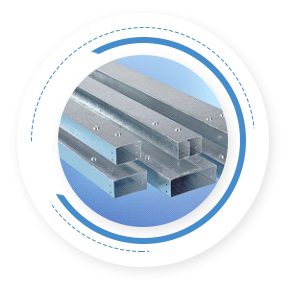

GI TRUNKING SYSTEM

KALISTER manufactures a full range of Metal Cable Trunkings: Single and multi compartments with accessories according to the highest standards of fabrication. All these products are available with various finishes applied in our factories to your demands. Metal Trunkings are available within variable thicknesses from 0.9 mm to 2 mm according to the specific project's specifications and as per customer's requests. Several types of trunkings and fittings with accessories are presented in our catalogue

KALISTER offers a comprehensive range of standard return flange surface trunking, and accessories, in single and multi-compartment.

Manufacturing Standard: BS EN 5008 - 1 (formerly BS 4678)

Material standard: Hot Dip Galvanized Sheet to BS EN 10142/3 Class 3. Stainless Steel S316

Standard Length: 2.44Mtr, and 3.00Mtr available upon request.

Cover Fixing is available in two different types:

Screw fix, using M5 blind rivets providing smooth edge to protect cables inside the trunking. Turnbuckle Fix (Quick Release Cam), using high tensile steel with aluminum caste bottoms, at intervals not exceeding 2 Mtrs. Trunking Finish options, ICMS offers other alternative for material finish upon the client's request: Hot Dip Galvanized to BS EN 1461 (formerly BS 729). Electrostatic powder coated, with different standard RAL colors. Epoxy PaintedThe return edge steel surface trunking system with strength and rigidity. Sizes up to 300 x 300 as standard, also available up to 650 wide to special order. 3 metre standard trunking lengths, other lengths available on request. Smooth return edges increase strength and rigidity.

FINISHES Standard Finish:

Pre-galvanized steel to BS EN 10142 & 3.Alternative Finish:

Epoxy/polyester powder coated Standard Grey /P to BS4800 00A05. Other RAL colours available on request.

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

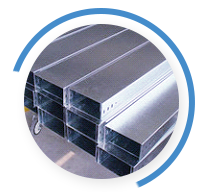

Underfloor Trunking System

KALISTER underfloorTrunking is manufactured from pre galvanized steel sheets in accordance with BS 4678, BS EN 50085-2-2 and IEC 61084-2-2. The system is designed for the distribution of Power, Voice and Data services in floors where metallic trunking is buried in the screed.. The system provides the simplest and most economical method of carrying services to feed outlets. The system incorporates numerous design features to ensure fast and simple installation. KALISTER underfloorTrunking system offers the following wide variants of accessories to suit your requirements.

- Metal UnderfloorTrunking,

- Junction boxes,

- Pedestal boxes,

- Service Out let Boxes

- Vertical Access Boxes

- Multiple Compartment Boxes

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

GI Conduit and Fittings

KALISTER bring forth various types of G.I. Conduits and Accessories as per the required standard of BS 4568 Part 2 1970 BS EN 50086-1:1994 in Class 4 and Class 3.

- BS 4568 Class 3 G.I. Conduits (Outside Galvanized) Available in 20mm, 25mm and 32mm Sizes

- BS 4568 Class 4 G.I. Conduits (Inside and Outside Galvanized) Available in 20mm 25mm and 32mm

- Variety of Conduit Accessories [Junction boxes, Tees, Bends, Couples, Saddles etc. & Fittings are available to provide a complete solution.

GI Conduit Accessories

Material: -Pig Iron/Malleable

Finishes: -Hot Dipp, Electro Galvanized & Black Enamel

60.3mm Internal Diameter x25.4mm Deep Tapped

M4 in mm Sizes & 2BA in imperial Sizes of 50.3mm

with Tapped Hole in base for earthing Screw.

supplied without cover & Screw unless ordered.Available Sizes in Conduit

Metric Imperial 20mm 3/4" 25mm 1" 32mm 1 1/4" 38mm 1 1/2" 50mm 2" -

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

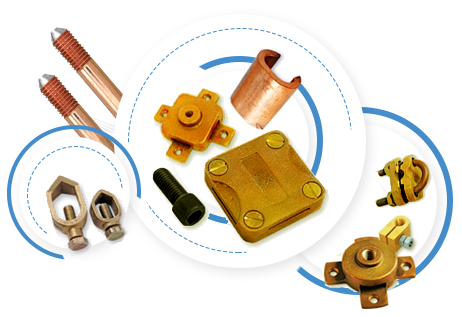

Earthing & Lightning Protection System

KALISTER copper bonded grounding rods are made by molecularly bonding 99.98 pure Electrolytic Copper on to a low Carbon steel core to a thickness up to 0.35 mm. They are highly resistant to corrosion, and because the steel used has a very high tensile strength, they can be driven by power hammers to great depths. Couplings threads are formed by rolling process to ensure thread strength and to maintain durability. The universally used thread rolling process raises the surfaces of the Rod. Thereby achieve the thread diameter greater that the Rod diameter. All the threads are Unified National Coarse. The counter-bored couplings are made from high copper content alloy. Connections to copper bonded rods can be by Mechanical clamps, compression or Exothermic welding system.

Earth rods are made in accordance to BS EN 50164-2, BS 7430 and Fittings to BS EN 50164-1

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

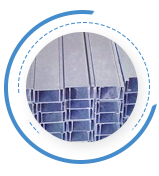

Steel Cable Tray and Accessories

KALISTER cable trays and fittings are manufactured in accordance with BS 61537:2002 and BS EN 10346:2009 for the smooth and easy installation of cable. We supply the cable tray in light , Medium and heavy guage produced in Pre Galvanized mild steel. Post Galvanized cable trays as per BS EN 10346 are also available for superior corrosion resistant. KALISTER cable trays are U shaped with 180 Deg return flange and manufactured from sheet up to 2 mm thickness. Tray bottom is perforated with longitudinal (BPL/RL type ) or transverse (BPL/RT type) slots for suitable cable cooling and reinforced with longitudinal ribs.

KALISTER also offer I Beam side rail design, which allows to the installer to easily cut, handle and install the tray while providing increased strength and rigidity. We have comprehensive line of accessories to allow for numerous cable management options.

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

GI Flush Steel Outlet Boxes

Our range of GI Box (galvanized iron box) is offered in different sizes, shapes and dimensions. Our product range is available at industry leading prices and is appreciated for the following features:

- Durability

- Superior finish

- Dimensionally accurate

- Excellent resistance to corrosion

- Abrasion resistant nature

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

Cable Glands & accessories

KALISTER Cable Glands deliver proven, secure electrical connections throughout the life cycle of the installation. Rugged construction and sealing technologies withstand harsh vibrations and Environments.

Technical Data

General Specification : BS 6121-1:2005

Materials

Glands - Bodies, Caps & Rings: Brass Seals - Nitrile Rubber Shrouds/Sleeves - Black Poly Vinyl Chloride (PVC) Earth Tag - Natural Brass Locknut - Natural Brass/Galvanized Finish - Natural Brass /Nickel Plated Entry Thread - Isometric (other threads available on request)

-

- PVC Conduits & Fittings

- UPVC Cable Ducts and Fittings

- PE Cable Ducts and Inner Ducts

- PVC Trunking System

- GI Trunking System

- Underfloor Trunking System

- GI Conduit and Fittings

- Earthing & Lightning Protection System

- Steel Cable Tray and Accessories

- GI Flush Steel Outlet Boxes

- Cable Glands and accessories

- Cable Terminal Lugs Accessories

CABLE TERMINAL & LUGS ACCESSORIES

Kalister Group has widest range of Cable Terminal Ends consisting of sizes from 0.5mm 2 to 1000mm2. Our products conforms to IS/BS & DIN specification. Kalister Group Cable Terminal Ends are approved by major OEM'S and leading project consultants.